AWS A5.15: ENiFe-CI

Suitable for repair welding on key high strength gray cast iron and spheroidal graphite cast iron, such as cylinders, engine bearers, gears, rollers, etc.

Email: max.wang@jthweld.com

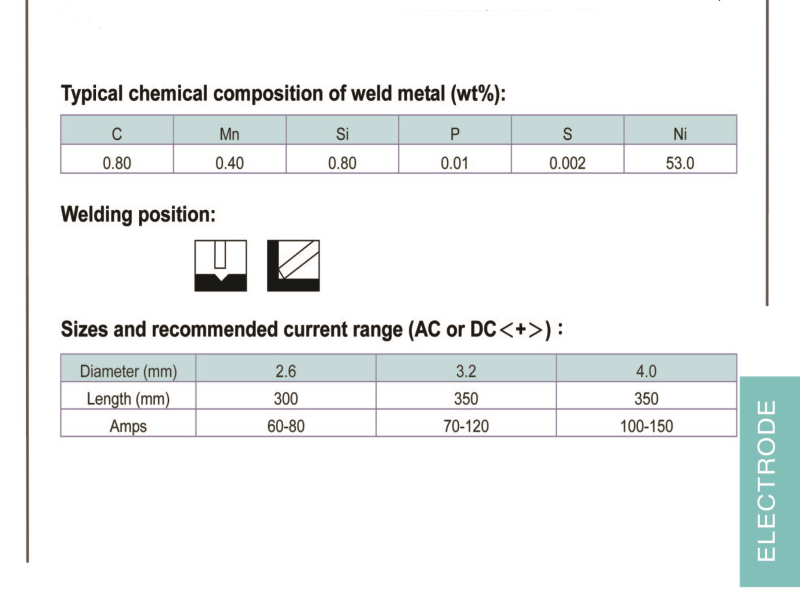

AWS A5.15: ENiFe-CI

Suitable for repair welding on key high strength gray cast iron and spheroidal graphite cast iron, such as cylinders, engine bearers, gears, rollers, etc.

Characteristics and Applications:

ENiFe-Cl is a covered electrode of Fe-Ni alloy core rod with graphite coating.

The weld metal provides lowexpansion coefficient, less hardening and good machining property.

lt is suitable for ductile cast iron,malleable cast iron and gray cast iron.

Satistied performance can be obtained specifically in the welding oflarge or high-restraint workpiece.

The toughness is higher than that of ENi-CI

Notes on usage:

1.Clean up the contaminations on the base metal and welding seam so as not to derogate the weld metalquality from crack and porosity.

2.Heat the welding portion to fully evaporate oil, liquor or solvent on it, normally the temperature is at around400~500℃.

3.Maintaining short arc length as possible is highly recommended. While welding with weave method, movingrange should be controlled within 3 times of the wire's dia.

4.Use intermittent weld and keep arc length short (not longer than 3")or the prolonged heating might causecrack on joint edge.Symmetrical intermittent weld should be applied to muilti-layer welding so as to balancethe heat stress.

5.Pre-heating and slow cool-down is sometimes required, according to the metal's type, shape and size.6.To alleviate shrinking stress, proceed peening on and off at the temperature above 540℃ after welding toprevent crack or distortion.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!