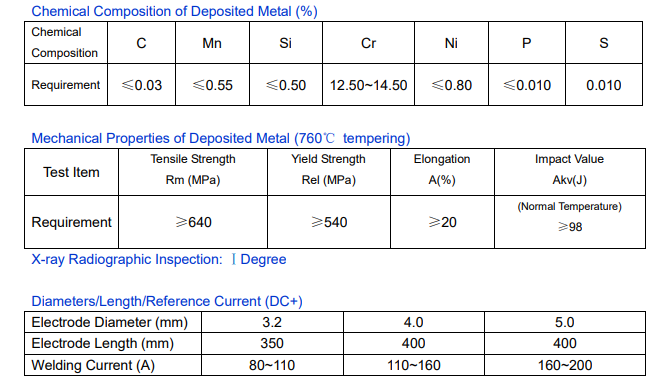

E410L-16

G200 E410L-16 is a kind of ultra-low-carbon Cr13 stainless steel electrode with lime-titania type coating. The coating is approaching to neutral slag. DCRP (Direct Current Reversed Polarity). It has excellent welding performance and optimum comprehensive mechanical properties of deposited metal.

Email: max.wang@jthweld.com

E410L-16

G200 E410L-16 is a kind of ultra-low-carbon Cr13 stainless steel electrode with lime-titania type coating. The coating is approaching to neutral slag. DCRP (Direct Current Reversed Polarity). It has excellent welding performance and optimum comprehensive mechanical properties of deposited metal.

Application: Used for welding compressor impeller X12Cr13 steel fillet weld, used for welding

steam turbine blades such as 0Cr13 and 1Cr13 stainless steel structures, and also used for

corrosion-resistant and wear-resistant surface overlaying.

Notes on Usages:

1. The electrodes must be baked under about 300℃ for an hour before welding.

2. The stains on the weldments, such as rust, oil stains, moisture, etc., must be cleared away

before welding.

3. The weldments should be preheated to 200-300℃ before welding.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!