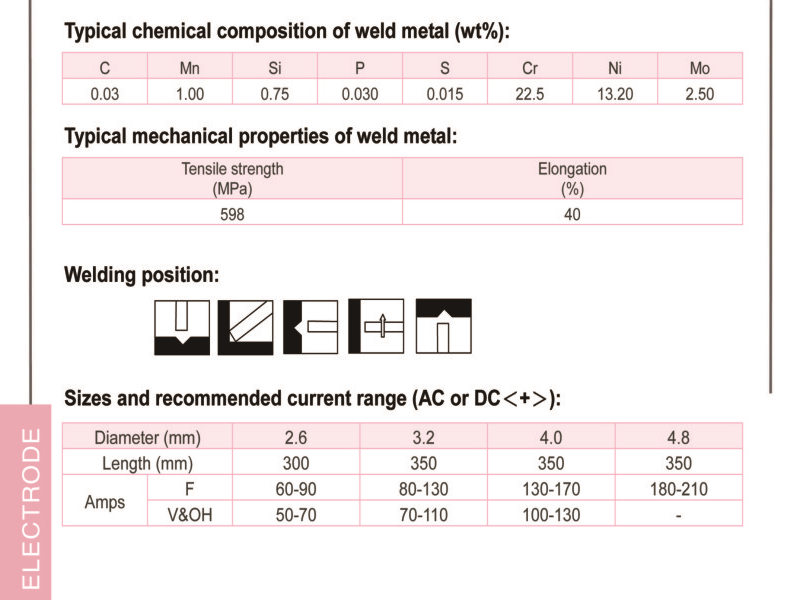

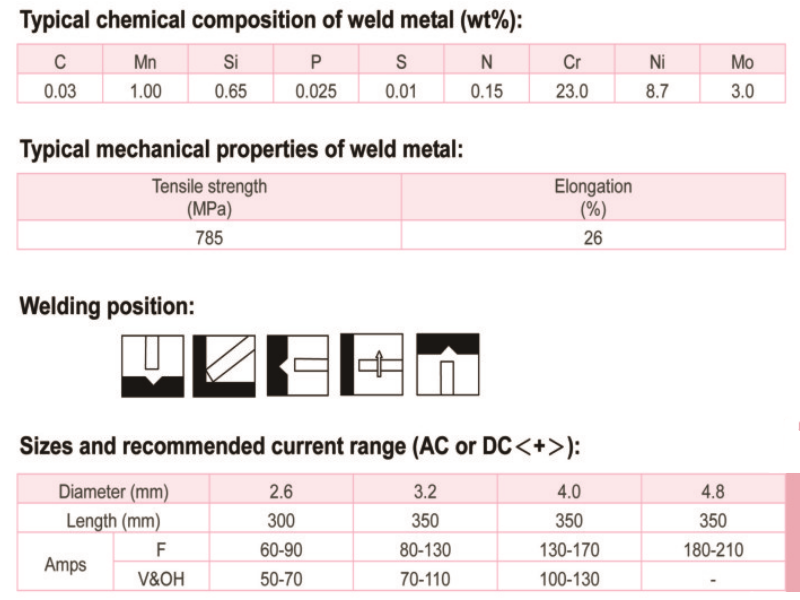

E308-16/E308L-16

Used for welding corrosion-resistant 0Cr19Ni9, 0Cr19Ni11Ti stainless steel structures below 300℃.

Email: max.wang@jthweld.com

E308-16/E308L-16

Standard

AWS A5.4: E308-16/E308L-16

Characteristics and Applications:

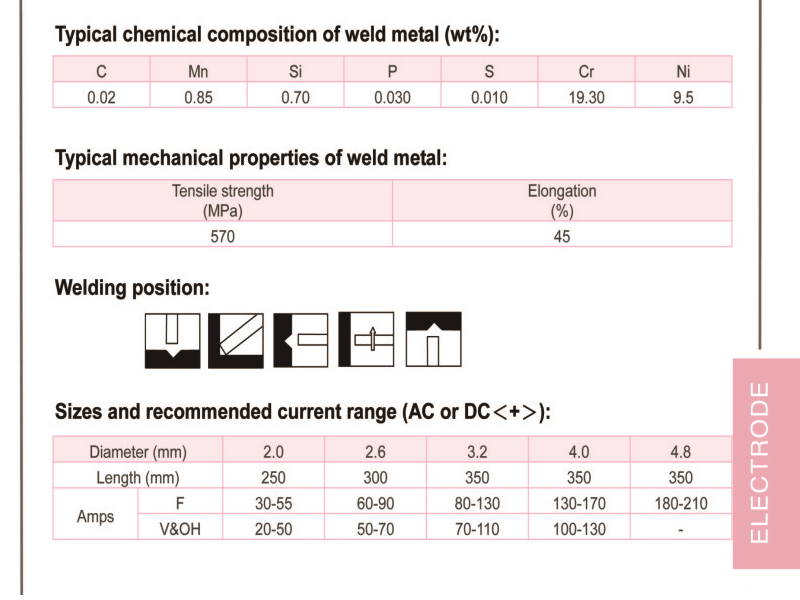

The weld metal of E308/ 308L is a 19Cr-10Ni austenite microstructure which contains limitedferrite Excellent performances in slag release, weld bead appearance,weldability, corrosion resistibility athigh temperature are all obtainable. lt is suitable for the welding of AISl-304 steel, AISl-301 steel and AISl-steel in all positions.

Proper base metal for E 308/308L: stainless thin plate, hoop, pipe, seamless pipe, thermal pipe, pressuvessel plate, steel bar, forge.

Notes on usage:

1.Clean up the contaminations on the base metal groove and pass to pass with stainless steel brush.

2.Maintaining short arc length as possible is highly recommended. While welding with weave method, movingrange should be controlled within 2.5 times of the wire's dia.

3.Dry the electrodes at 250~300℃ for 60 minutes before use. Take out consumables for half dayconsumption and keep in the environment at 100~150℃ during welding process.

4. Use lower current to prevent from cracking and minimize base metal dilution.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!