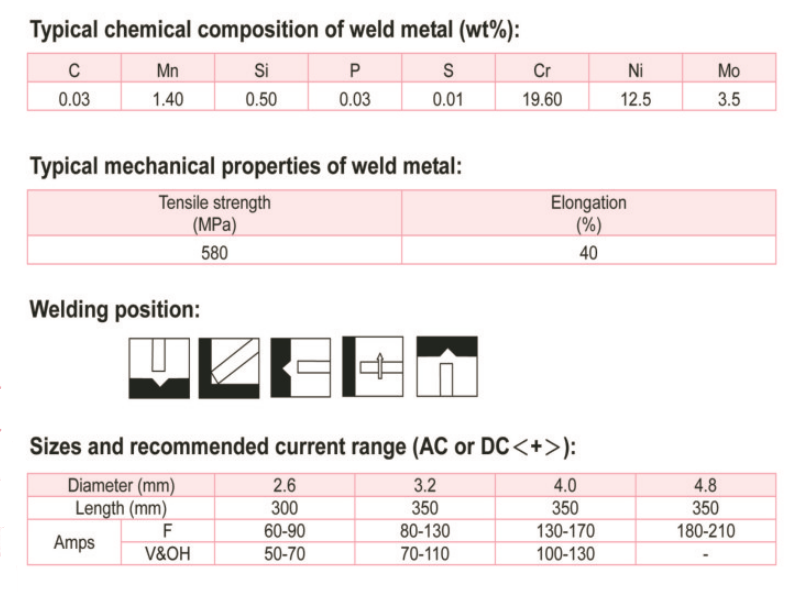

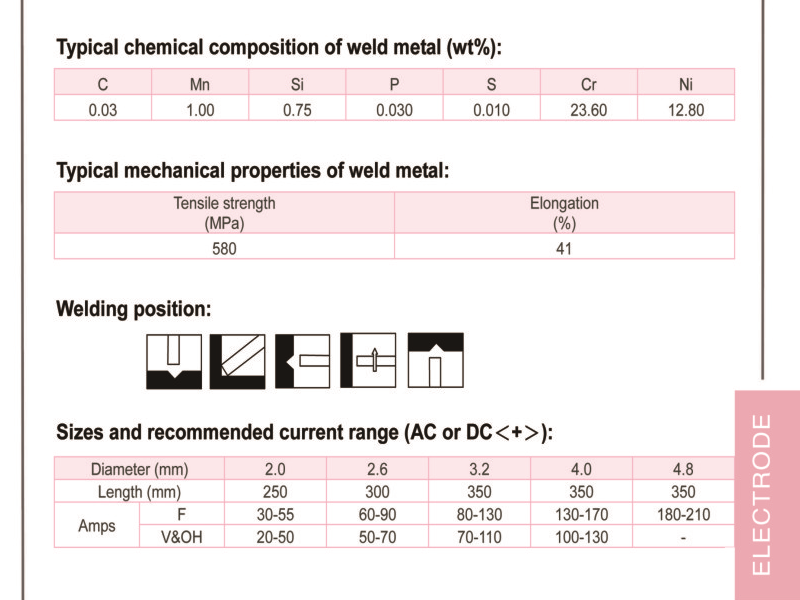

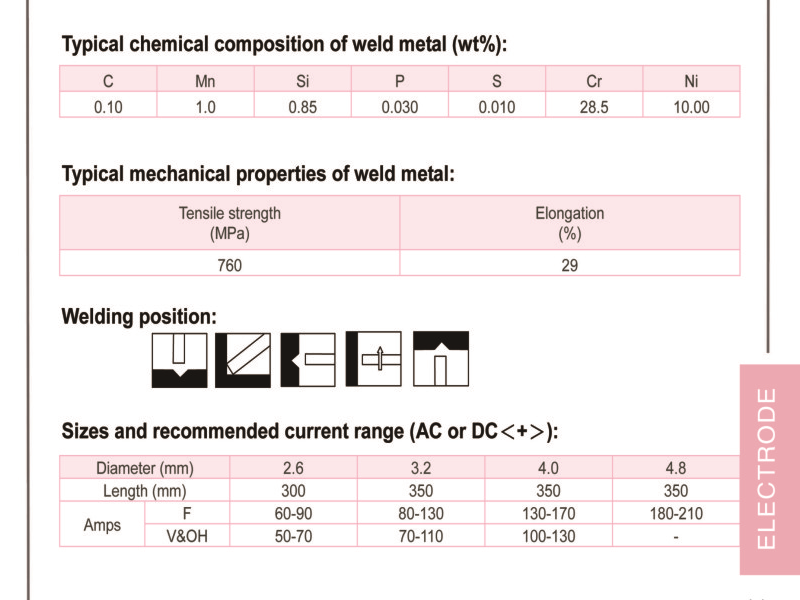

E309MoL

E309MoL is superior to E309/309L in crack resistance and corrosion resistance at the high temperaturedue to higher Mo content. Low carbon content of weld metal makes it suitable for dissimilar metal welding ofjoining mild steel to stainless steel and reducing inter-granular corrosion.

Email: max.wang@jthweld.com

E309MoL

AWS A5.4 E309Mo/E309LMo-16

Characteristics and Applications:

E309MoL is superior to E309/309L in crack resistance and corrosion resistance at the high temperaturedue to higher Mo content. Low carbon content of weld metal makes it suitable for dissimilar metal welding ofjoining mild steel to stainless steel and reducing inter-granular corrosion.

Notes on usage:

1.Clean up the contaminations on the base metal, groove and pass to pass with stainless steel brush.

2.Maintaining short arc length as possible is highly recommended.While welding with weave method, movingrange should be controlled within 2.5 times of the wire's dia.

3. Dry the electrodes at 250~300℃ for 60 minutes before use. Take out consumables for half dayconsumption and keep in the environment at 100~150℃ during welding process.

4.Use lower current to prevent from cracking and minimize base metal dilution whiling in welding dissimilarmetals or root pass of clad steel.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!