JTH-350

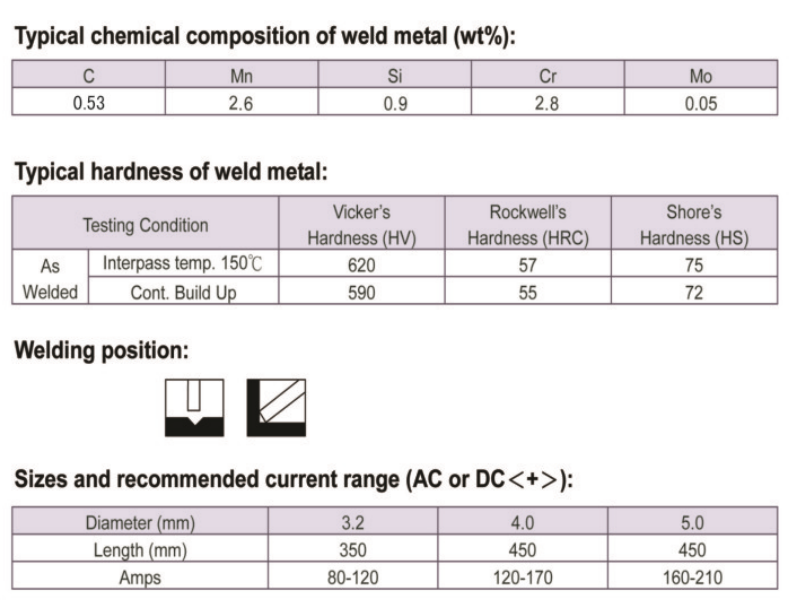

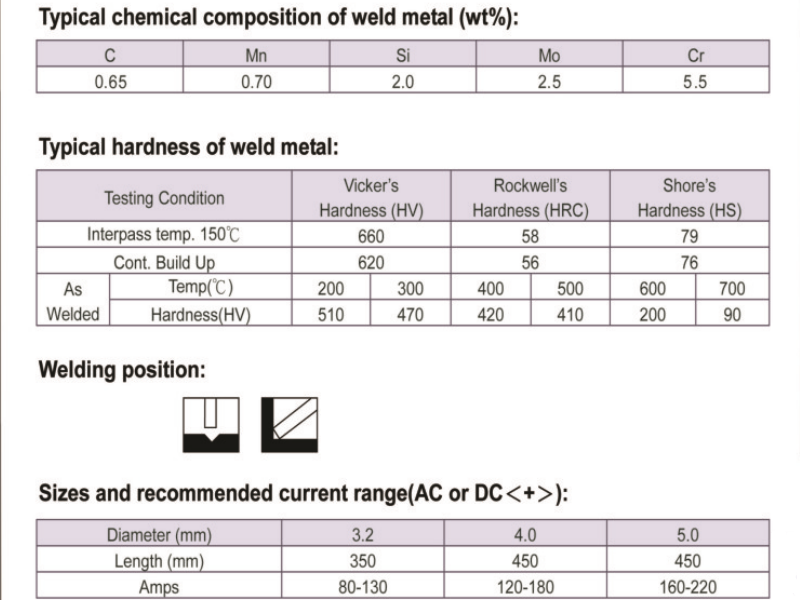

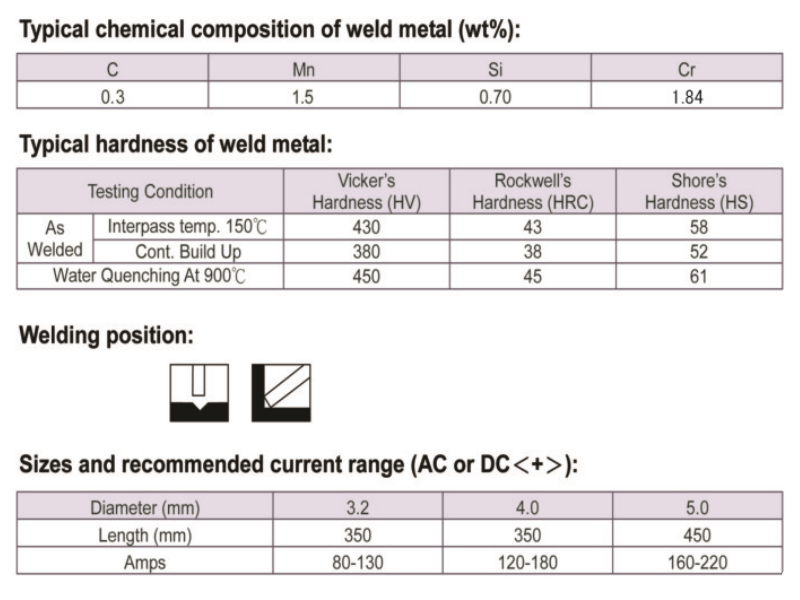

JT-H350 is a low hydrogen type electrode. The weld metal is sorbite structure (Ferrite + cementite). Theweld metal has good mechanical properties, excellent resistance to abrasion accompanied with impact. It issuitable for the welding of shovel tooth, bulldozer blades, crane wheels and buckets

Email: max.wang@jthweld.com

JTH-350

Characteristics and Applications:

JT-H350 is a low hydrogen type electrode. The weld metal is sorbite structure (Ferrite + cementite). Theweld metal has good mechanical properties, excellent resistance to abrasion accompanied with impact. It issuitable for the welding of shovel tooth, bulldozer blades, crane wheels and buckets

Notes on usage:

1.Dry the electrodes at 300-350℃ for 30-60 minutes before use.

2.Clean up the contaminations on the steel.

3.Use back-step method to prevent arc starting from blowholes and stay for 3-5 seconds before every end-up.

4.Maintaining short arc length as possible is highly recommended.While welding with weave method, movirrange should be controlled within 2.5 times of the wire's dia.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!