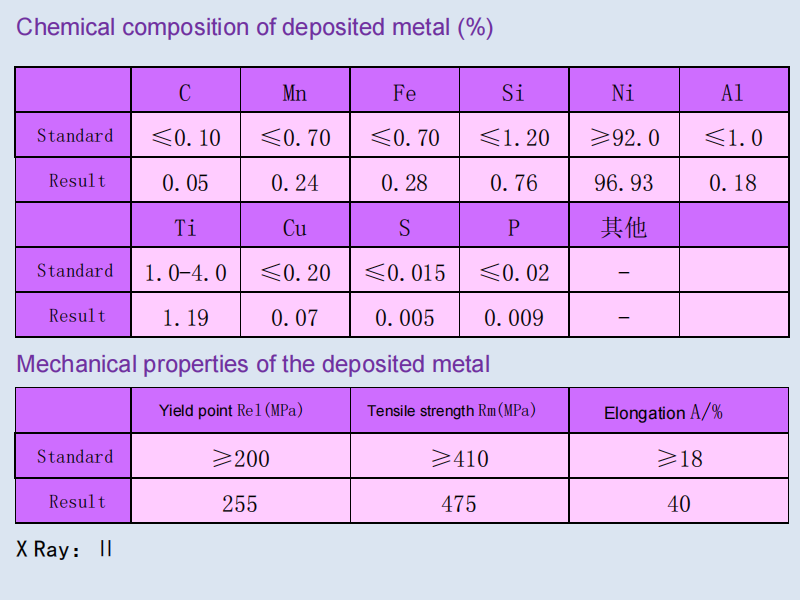

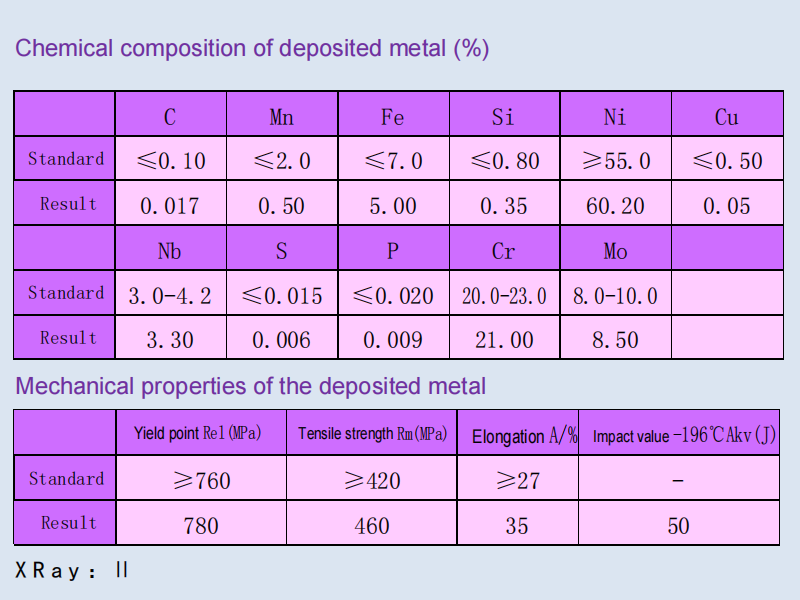

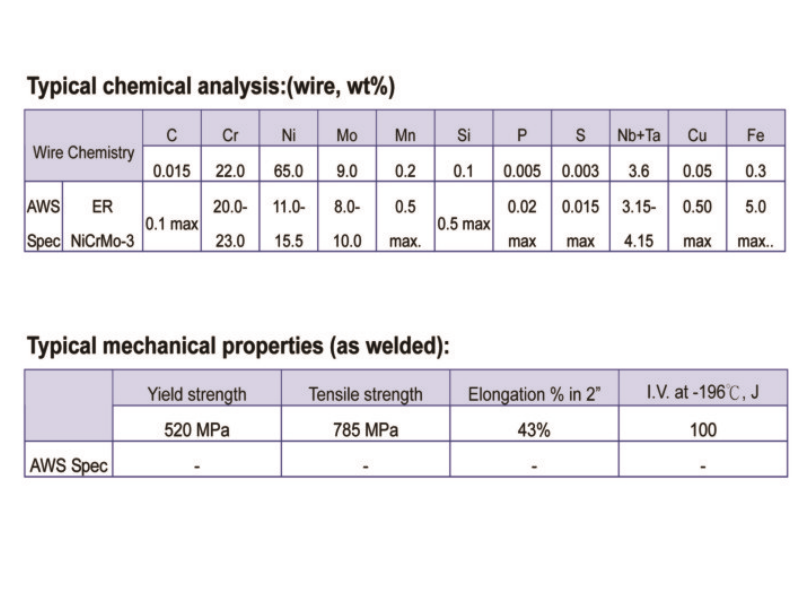

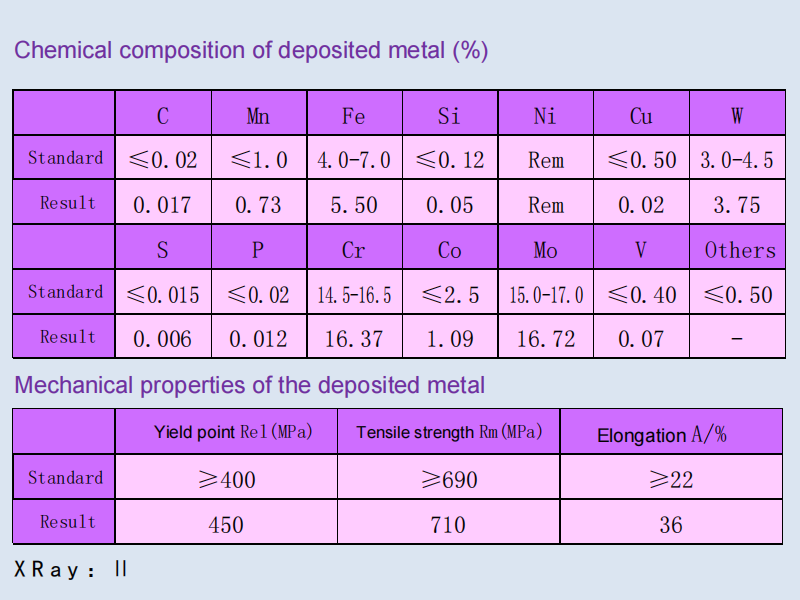

AWS A5.11 ENiCrMo-4

ENiCrMo-4 is a low-hydrogen type electrode for nickel-based alloys. Its chemical composition code is NiCr15Mo15Fe6W4. It is suitable for direct current reverse polarity welding, with excellent welding performance. The mechanical properties of the deposited metal and its resistance to pitting corrosion, stress corrosion and high-temperature oxidation are excellent. It can be used for all-position welding.

Email: max.wang@jthweld.com

AWS A5.11 ENiCrMo-4

ENiCrMo-4 is a low-hydrogen type electrode for nickel-based alloys. Its chemical composition code is NiCr15Mo15Fe6W4. It is suitable for direct current reverse polarity welding, with excellent welding performance. The mechanical properties of the deposited metal and its resistance to pitting corrosion, stress corrosion and high-temperature oxidation are excellent. It can be used for all-position welding.

Applications:

It is mainly used for welding HASTELLOY C-276 and other nickel-based alloys, and can also be used for surface welding of carbon steel.

Notes:

1. The welding rods should be baked at 300℃ for 1 hour before welding, and they should be used immediately after baking.

2. Before welding, all impurities such as rust, oil, and moisture on the surface of the workpiece must be removed.

3. During welding, short arc operation and narrow weld bead method should be used.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!