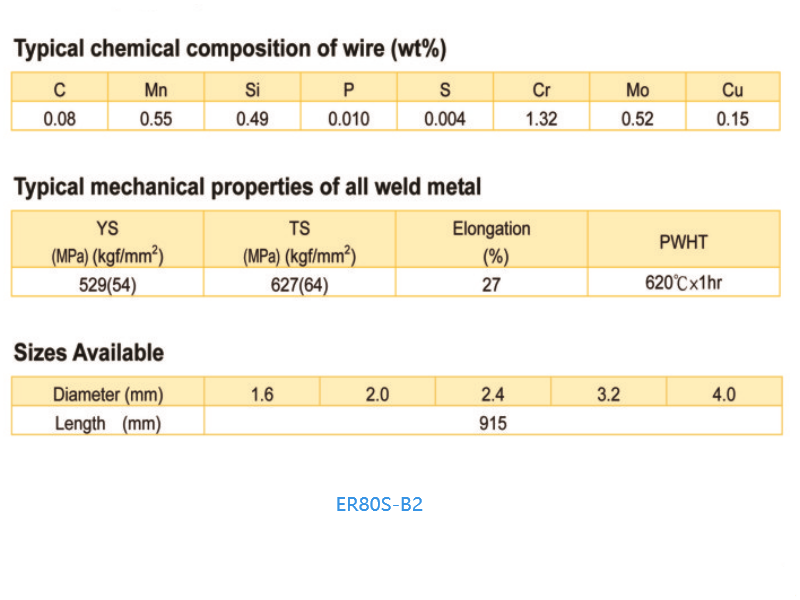

AWS A5.28 ER80S-B2

ER80S-B2 with 1.25% Cr and 0.5% Mo,is designed for welding low-alloy steels with high tensile strengthand creep-resistant steels such as ASTM type: A199-76, A200-75, A213-76d,A335-76,A369-76,A387-76.Suitable for pipelines and pressure vessels with operating temperatures at about 500℃.

Email: max.wang@jthweld.com

AWS A5.28 ER80S-B2

Characteristics and Applications:

ER80S-B2 with 1.25% Cr and 0.5% Mo,is designed for welding low-alloy steels with high tensile strengthand creep-resistant steels such as ASTM type: A199-76, A200-75, A213-76d,A335-76,A369-76,A387-76.Suitable for pipelines and pressure vessels with operating temperatures at about 500℃.

Notes on Usage:

1.Use DC(DCEN) polarity and 100% Argon gas at proper flow rate (10-15 L/min, max. wind 1 m/sec).2. Trailer Shield is required to ensure the weld pool completely shielded by inert gas until solidification iscomplete and no porosity problem.

3.Select right gas cup size and employ proper stick out of tungsten electrode.

4.Be sure to clean up the contaminations on the base metal and welding seam so as not to derogate theweld metal quality from particles.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!