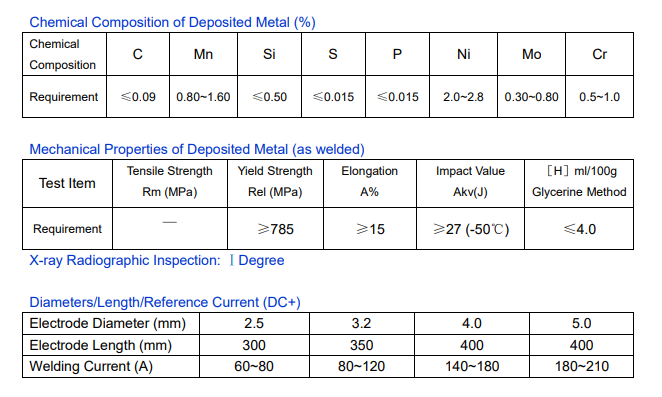

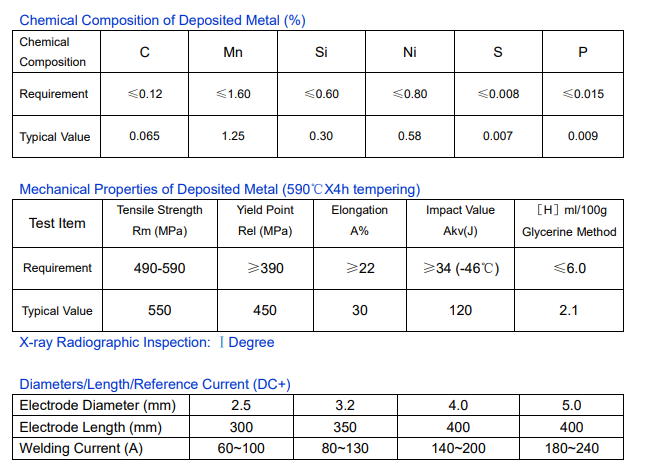

E7015-G

J507DR is a kind of carbon steel electrode with super low-hydrogen natrium type coating and high toughness. It is specially used for pressure vessel. DCRP (Direct Current Reversed Polarity). All-position welding. It has excellent plasticity, low temperature toughness and crack-resistance and good technological performance

Email: max.wang@jthweld.com

E7015-G

AWS A5.5 E7015-G

J507DR is a kind of carbon steel electrode with super low-hydrogen natrium type coating and high toughness. It is specially used for pressure vessel. DCRP (Direct Current Reversed Polarity). All-position welding. It has excellent plasticity, low temperature toughness and crack-resistance and good technological performance.

Application: specially used for the welds of strength low-alloy steel pressure vessel with the higher

requirements of high impact toughness, the welds between strength low-alloy steel and low-alloy heat-resistant steel , the welds between strength low-alloy steel and low temperature low-alloy steel.

Notes on Usages:

1. 1.The electrodes must be baked under 350~380℃ for 1-2 hours before welding and used as

soon as baking is completed.

2. The stains on the weldments, such as rust, oil stains, moisture, etc., must be cleared away

before welding.

3. When welding, short arc must be used, and stringer bead is suitable

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!