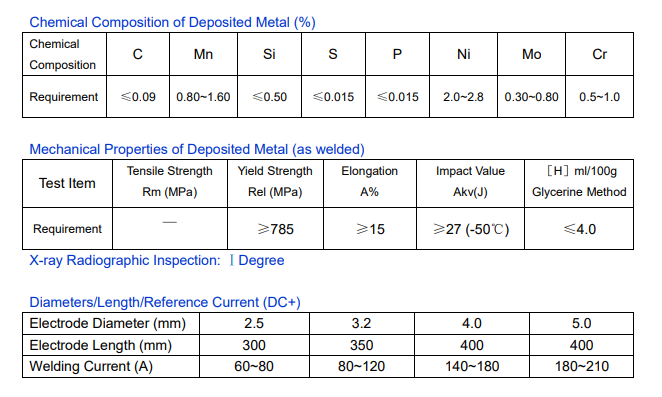

E9015-G

V840 is a kind of low-alloy high strength steel electrode with low-hydrogen natrium type coating. It has high strength, ductility and toughness, specially excellent low temperature impact toughness and crack-resistance. DCRP (Direct Current Reversed Polarity). All-position welding.

Email: max.wang@jthweld.com

E9015-G

V840 is a kind of low-alloy high strength steel electrode with low-hydrogen natrium type coating. It has high strength, ductility and toughness, specially excellent low temperature impact toughness and crack-resistance. DCRP (Direct Current Reversed Polarity). All-position welding.

Application: Used for welding pressure vessels made of low-alloy high strength steel with yield

point Rel >785MPa and some other structures.

Notes on Usages:

1. The electrodes must be baked under 400℃ for 2 hours.

2. The electrodes must be put into a 100-150℃ insulation can so as to prevent coating from

moisture absorption during welding.

3. The electrodes must be baked after being taken out more than 2 hours from an insulation can

or absorbing moisture due to other reasons, but the electrodes can only be baked two times.

4. The stains on the weldments, such as rust, oil stains, moisture, etc., must be cleared away

before welding.

5. When welding, short arc must be used, and stringer bead is suitable.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!