H09MnSH/SJ204SH

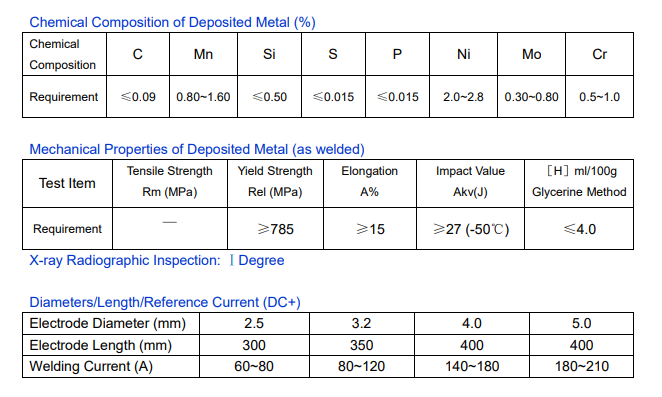

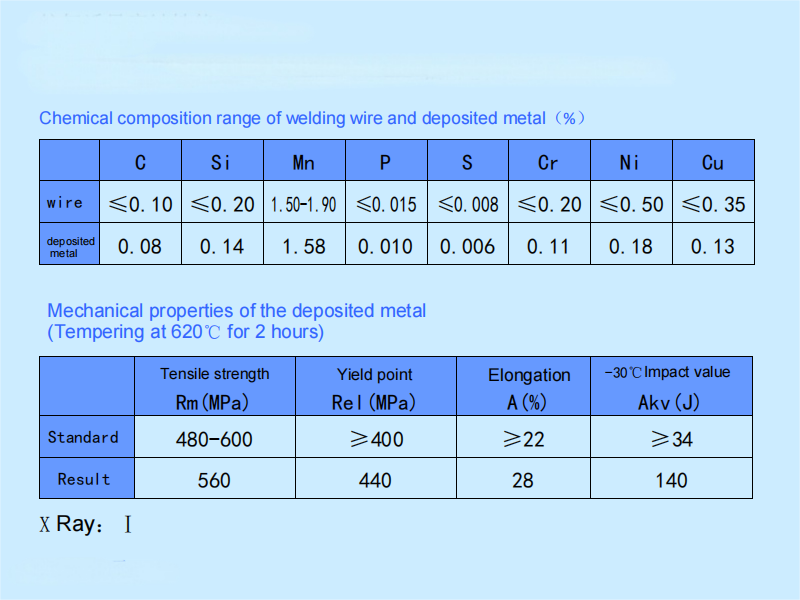

H09MnSH is a copper-coated submerged arc welding wire for anti-hydrogen steel. When used in conjunction with the corresponding flux SJ204SH for submerged arc automatic welding, the weld bead formation is good, slag removal from the groove is easy, and the S and P contents in the deposited metal are low.

Email: max.wang@jthweld.com

H09MnSH/SJ204SH

H09MnSH is a copper-coated submerged arc welding wire for anti-hydrogen steel. When used in conjunction with the corresponding flux SJ204SH for submerged arc automatic welding, the weld bead formation is good, slag removal from the groove is easy, and the S and P contents in the deposited metal are low. It has excellent anti-hydrogen-induced corrosion performance.

Application:

It is used for welding steel prone to anti-hydrogen-induced corrosion cracks (HIC), such as 16MnR (HIC).

Notes:

1. The flux must be baked at 300-400℃ for 1-2 hours before use. The welding wire should be dry, free of oil and rust before use. Status.

2. The welding area must be thoroughly cleaned of oil stains, rust, moisture and other surface impurities.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!