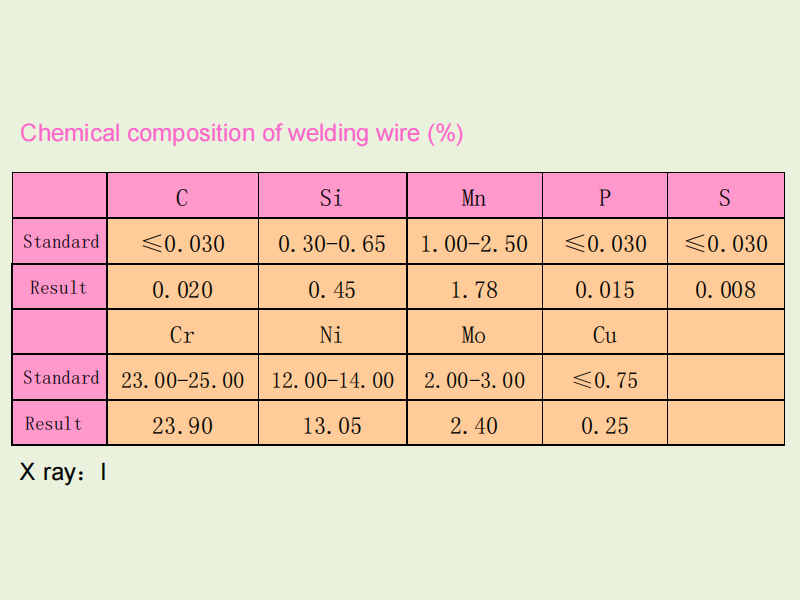

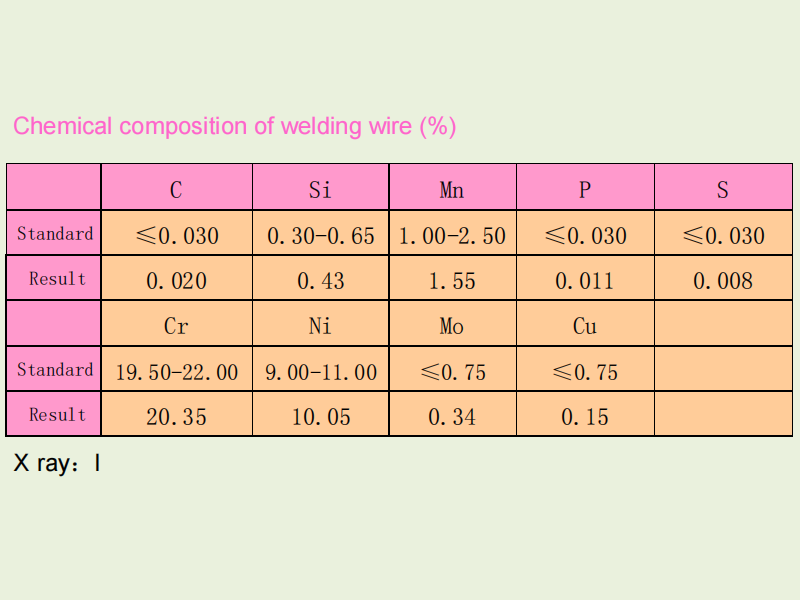

AWS A5.9 ER308L

ER308L(-196℃) is a MIG and TIG welding wire for ultra-low carbon stainless steel. It has excellent welding performance. The deposited metal is of ultra-low carbon type, which reduces the precipitation of intergranular carbides, resulting in excellent intergranular corrosion resistance.

Email: max.wang@jthweld.com

AWS A5.9 ER308L

ER308L(-196℃) is a MIG and TIG welding wire for ultra-low carbon stainless steel. It has excellent welding performance.

The deposited metal is of ultra-low carbon type, which reduces the precipitation of intergranular carbides, resulting in excellent intergranular corrosion resistance. Especially at (-196℃), it has excellent impact toughness.

Applications:

It is used for welding ultra-low carbon 00Cr19Ni10 or 0Cr18Ni10Ti stainless steel. It has good impact toughness at (-196℃) and is suitable for welding of LNG storage tanks and weld seams.

Notes on Usages:

1. The welding area must be thoroughly cleaned of oil, rust, moisture and other surface impurities to prevent the formation of pores, cracks, etc. during welding. During the cleaning process, the bevel surface and its surrounding areas should show a metallic luster.

2. Before welding, the oil, dirt, rust and other contaminants on the welding wire surface should be removed.

3. To obtain good mechanical properties of the weld seam, the recommended shielding gas for MIG welding is Ar + 2% O2, with a flow rate of 20-25 L/min being preferable. For TIG welding, the recommended shielding gas is pure argon, with a purity of over 99.99% and a flow rate of 8-15 L/min.

4. During the welding process, the size of the welding line energy directly affects the mechanical properties and crack resistance of the deposited metal, and should be given more attention.

5. The above welding methods, conditions and specifications are for reference only. Users should conduct process evaluation based on their own welding characteristics before using the welding wire for formal product welding.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!