EQ316L/SJ306D/SJ205D

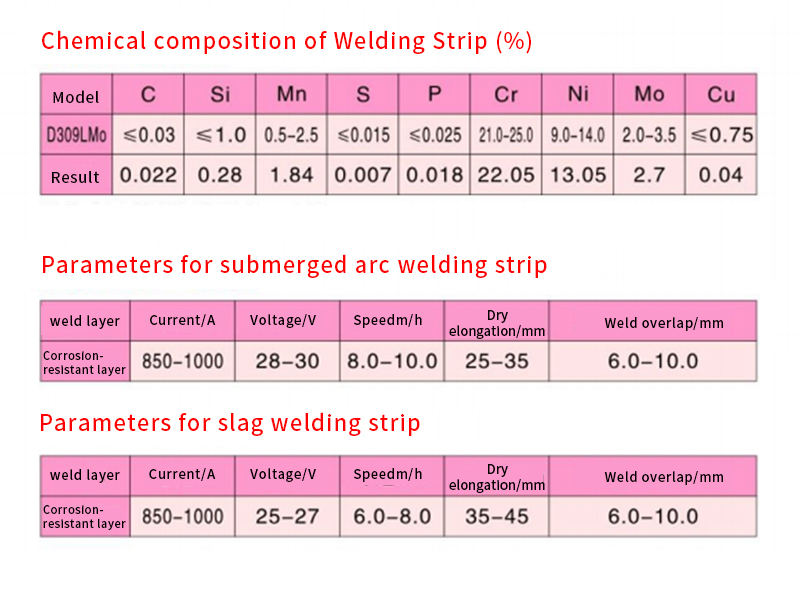

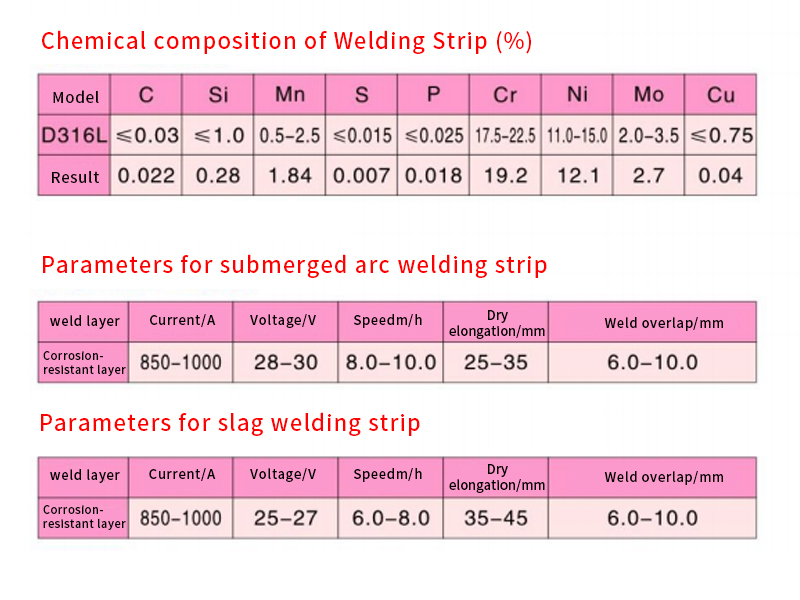

D316L is a welding strip for stainless steel; SJ306D is a neutral sintered submerged arc welding flux with a base alkalinity of 1.0, featuring excellent high-temperature slag removal performance and a smooth and flat surface finish of the weld metal. The main alloy elements are basically not burned off and do not increase carbon content.

Email: max.wang@jthweld.com

EQ316L/SJ306D/SJ205D

D316L is a welding strip for stainless steel; SJ306D is a neutral sintered submerged arc welding flux with a base alkalinity of 1.0, featuring excellent high-temperature slag removal performance and a smooth and flat surface finish of the weld metal. The main alloy elements are basically not burned off and do not increase carbon content. It is a dedicated welding flux for D316L ID309LMo type stainless steel strip submerged arc overlay welding. SJ205D is a dedicated welding flux for stainless steel strip electroslag overlay welding, suitable for D308L ID309L ID347L ID316L type welding strips.

Usage: For overlay welding of corrosion-resistant layers.

Notes:

1. The flux must be baked at 300-400 degrees for 2 hours before use. The welding tape should be dry, free of oil and rust.

2. The welding area must be thoroughly cleaned of oil, rust, moisture, etc.

3. According to the user's situation, the content of deposited metal and deposited metal ferrite can be adjusted.

4. The above welding process parameters are for reference only.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!