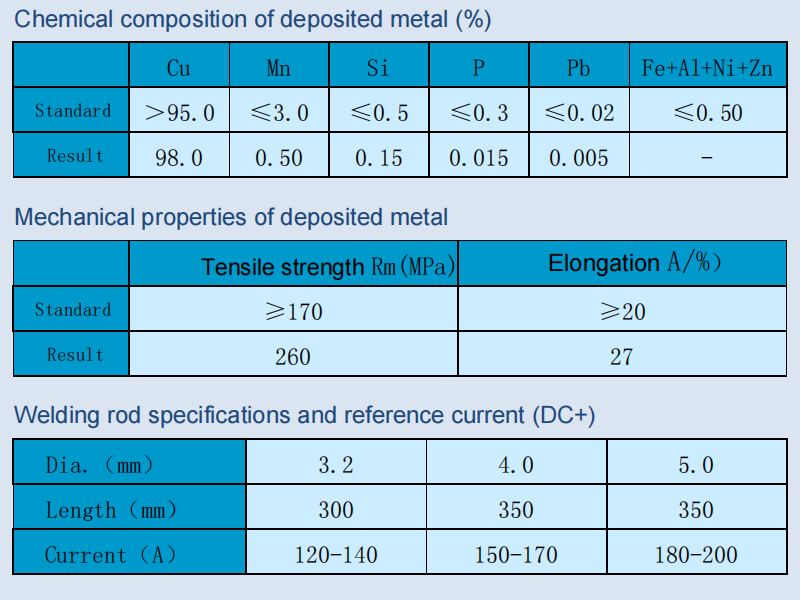

T107/AWS A5.6 ECuSi

T107 is a pure copper welding rod with pure copper as the welding core and low-hydrogen type coating. It has good mechanical properties and excellent corrosion resistance to air and seawater. It is not suitable for welding oxygen-containing copper and electrolytic copper. When using a direct current power supply, the welding rod is connected to the positive pole, resulting in a stable arc and good formation.

Email: max.wang@jthweld.com

T107/AWS A5.6 ECuSi

T107 is a pure copper welding rod with pure copper as the welding core and low-hydrogen type coating. It has good mechanical properties and excellent corrosion resistance to air and seawater. It is not suitable for welding oxygen-containing copper and electrolytic copper. When using a direct current power supply, the welding rod is connected to the positive pole, resulting in a stable arc and good formation.

Applications:

It is mainly used for welding conductive copper bars, copper heat exchangers, seawater conduits for ships, and other copper structural components. It can also be used for overlay welding of carbon steel parts that are resistant to seawater corrosion.

Notes on usage:

1. Before welding, the welding rods must be baked at around 200℃ for 1 hour. All impurities such as moisture, oil stains, and oxides on the surface of the weldment must be removed before welding can be carried out.

2. Under normal circumstances, the preheating temperature should be controlled between 400-500℃. During welding, a short arc should be used and a reciprocating linear motion should be adopted, which can improve the formation of the weld.

3. For longer weld seams, the step-back welding method should be used. The welding speed should be as fast as possible. When performing multi-layer welding, the slag between layers must be removed. After welding, the weld seam should be struck with a flat-head hammer to relieve stress and improve the quality of the weld.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!