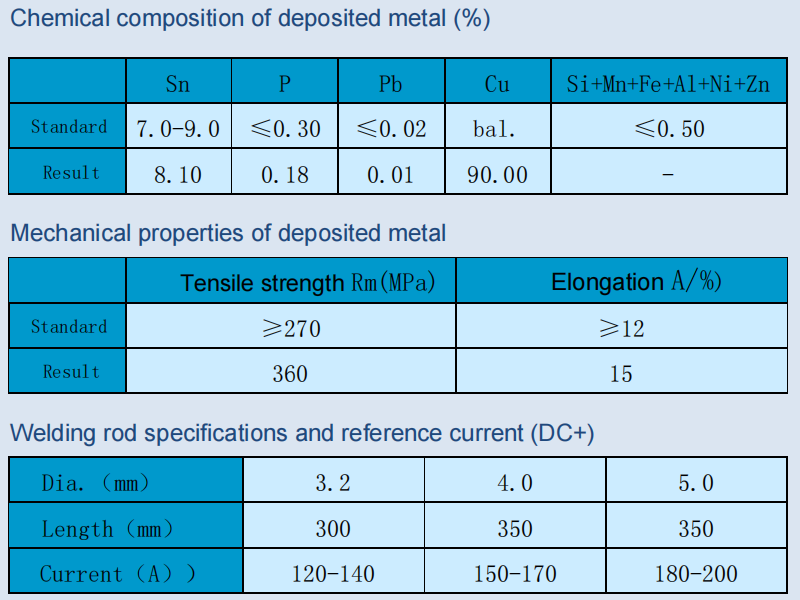

T227/AWS A5.6 ECuSn-C

T227 is a type of welding rod with tin-phosphorus bronze as the core and low-hydrogen copper alloy coating. It has certain strength, good plasticity, impact resistance, wear resistance and corrosion resistance. Its features include excellent welding process performance and wide applicability. When using a direct current power supply, the welding rod is connected to the positive pole.

Email: max.wang@jthweld.com

T227/AWS A5.6 ECuSn-C

T227 is a type of welding rod with tin-phosphorus bronze as the core and low-hydrogen copper alloy coating. It has certain strength, good plasticity, impact resistance, wear resistance and corrosion resistance. Its features include excellent welding process performance and wide applicability. When using a direct current power supply, the welding rod is connected to the positive pole.

Applications:

In addition to being suitable for welding pure copper, brass, phosphor bronze and other similar and dissimilar metals, it can also be widely used for welding phosphor bronze shaft linings, ship propeller blades, etc., as well as for repairing and welding cast iron.

Notes on Usage:

1. The welding rods should be baked at around 200℃ for 1 hour before welding. The impurities such as moisture, oil stains, and oxides on the surface of the weldment must be removed completely before welding.

2. The preheating temperature before welding: phosphor bronze is 150-250℃, pure copper is approximately 450℃, and carbon steel is about 200℃.

3. Immediately after welding, use a flat-head hammer to strike the weld seam to refine the grains and eliminate the stress.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!