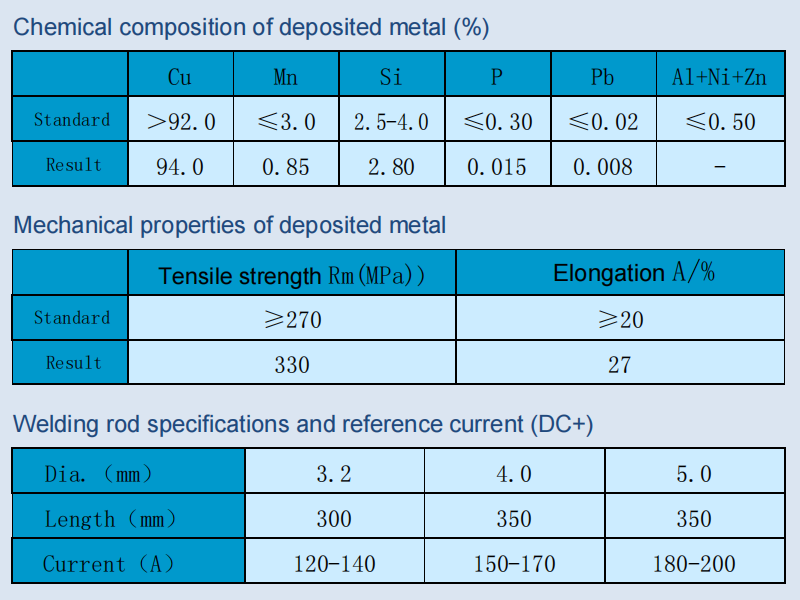

T207/AWS A5.6 ECuSi

T207 is a silicon bronze welding core and a low-hydrogen alloy welding rod. It has good mechanical properties and exhibits excellent corrosion resistance to inorganic acids other than nitric acid, most organic acids, and seawater. It is not suitable for welding oxygen-containing copper and electrolytic copper.

Email: max.wang@jthweld.com

T207/AWS A5.6 ECuSi

T207 is a silicon bronze welding core and a low-hydrogen alloy welding rod. It has good mechanical properties and exhibits excellent corrosion resistance to inorganic acids other than nitric acid, most organic acids, and seawater. It is not suitable for welding oxygen-containing copper and electrolytic copper.

Applications:

It is applicable for welding copper, silicon bronze, and brass, as well as for overlay welding of inner linings of chemical machinery pipelines.

Notes on usage:

1. The welding rods must be baked at 350℃ for 1-2 hours before welding.

2. The moisture, oil stains, oxides and other impurities on the surface of the weldment must be removed completely before welding.

3. When welding molybdenum silicon copper or overlaying welding on steel, no preheating is required. The preheating temperature for welding pure copper is 450℃, and for welding brass it is 300℃.

4. Immediately after welding, use a flat-head hammer to strike the weld seam to refine the grain structure and eliminate stress.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!