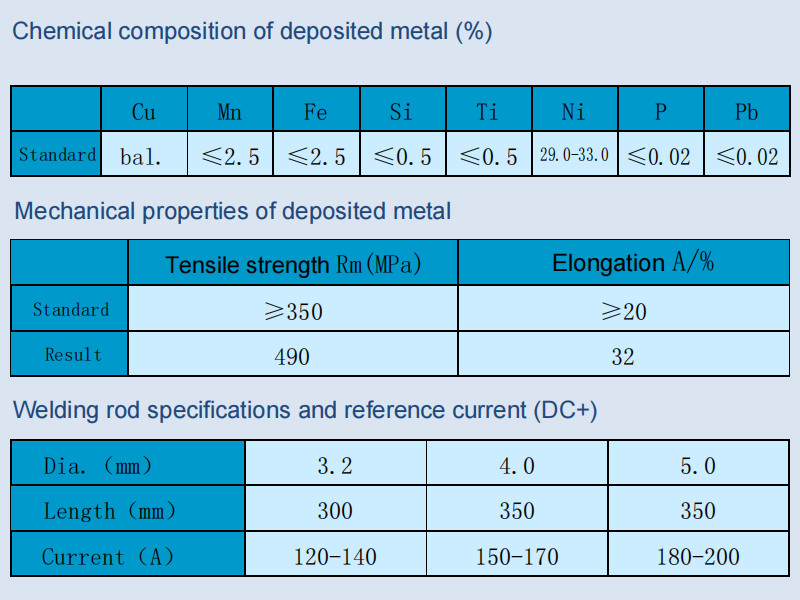

T307/AWS A5.6 ECuNi

T307 is a copper 70-nickel 30 alloy as the welding core and a low-hydrogen copper-nickel electrode as the coating. It uses a direct current power supply, with the electrode connected to the positive pole. This electrode has a stable arc and good weld formation.

Email: max.wang@jthweld.com

T307/AWS A5.6 ECuNi

T307 is a copper 70-nickel 30 alloy as the welding core and a low-hydrogen copper-nickel electrode as the coating. It uses a direct current power supply, with the electrode connected to the positive pole. This electrode has a stable arc and good weld formation.

Application:

It is mainly used for 70-30 copper-nickel alloy, or 70-30 copper-nickel alloy / 645-Ⅲ steel composite metals and 70-30 copper-nickel alloy as the overlay layer, and 645-Ⅲ steel as the base layer in the composite metal for lining structures.

Notes:

1. The welding rods should be baked at around 300℃ for 1 hour before welding.

2. The moisture, oil stains, oxides and other impurities on the surface of the weldment must be removed completely before welding can be carried out.

3. If preheating is not done before welding, the interlayer temperature should be lower than 150℃. Short arc welding should be adopted.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!