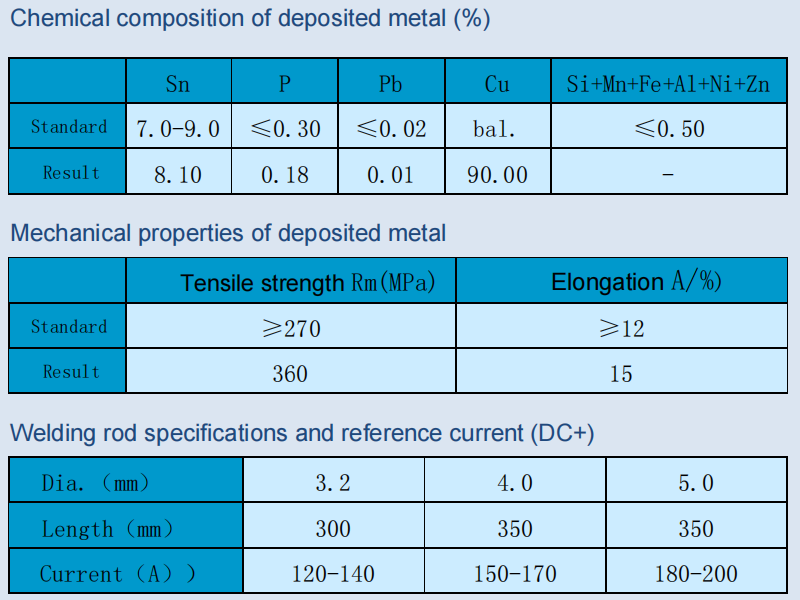

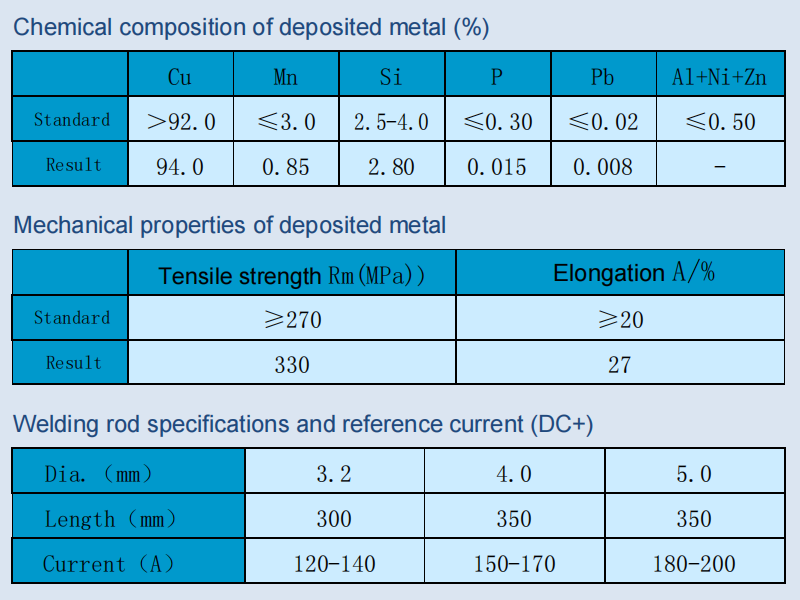

T237/AWS A5.6 ECuAl-A2

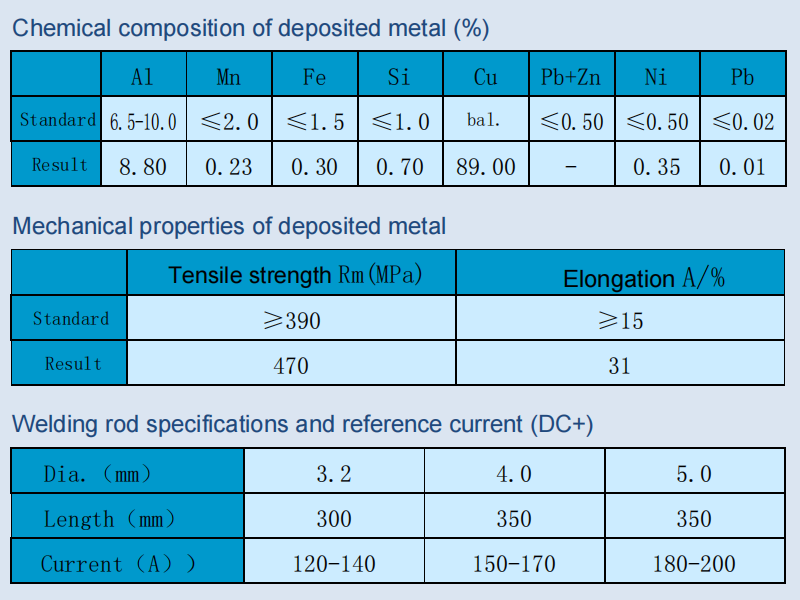

T237 is a type of welding rod with an aluminum-manganese bronze as the core and a low-hydrogen copper alloy coating. It has excellent wear resistance and corrosion resistance. It is operated with a direct current power supply, with the welding rod connected to the positive pole.

Email: max.wang@jthweld.com

T237/AWS A5.6 ECuAl-A2

T237 is a type of welding rod with an aluminum-manganese bronze as the core and a low-hydrogen copper alloy coating. It has excellent wear resistance and corrosion resistance. It is operated with a direct current power supply, with the welding rod connected to the positive pole.

Applications:

Widely used for welding aluminum bronze and other copper alloys, copper alloys and steel, as well as for repairing cast iron. Such as welding of various chemical machinery, seawater coolers, valves, pumps, cylinders, etc., and repair of ship propellers.

Notes on Usage:

1. Before welding, the welding rods should be baked at around 200℃ for 1 hour. The impurities such as moisture, oil stains, and oxides on the surface of the weldment must be removed completely before welding.

2. For the welding of aluminum bronze and the overlay welding of carbon steel, thin parts do not require preheating, while thick parts must be preheated to around 200℃.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!