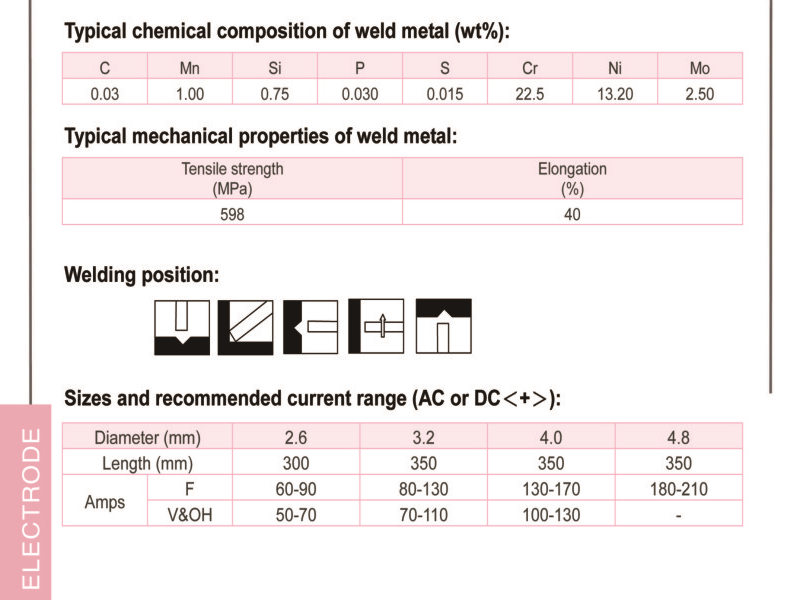

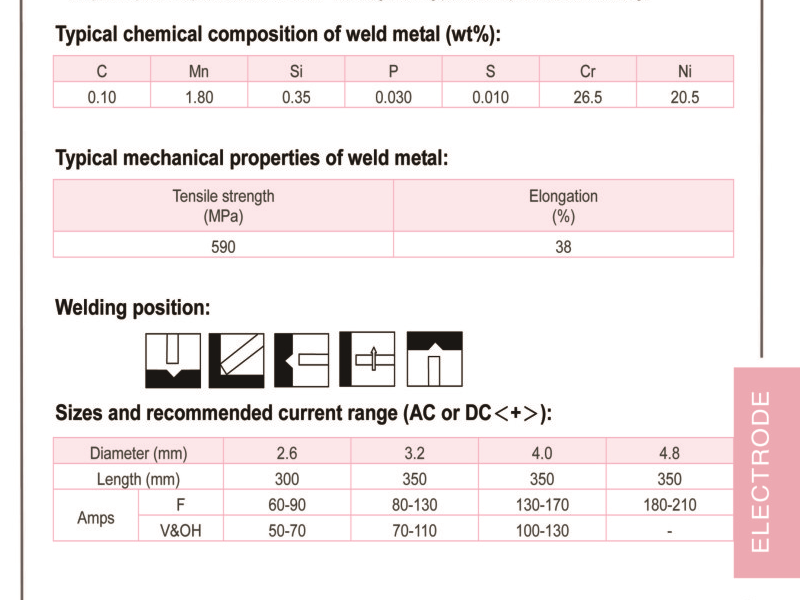

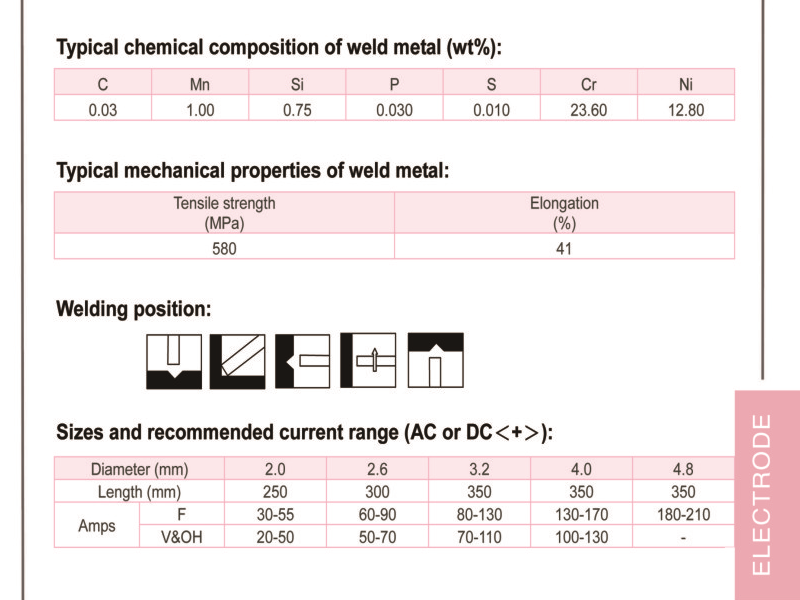

E310Mo-16

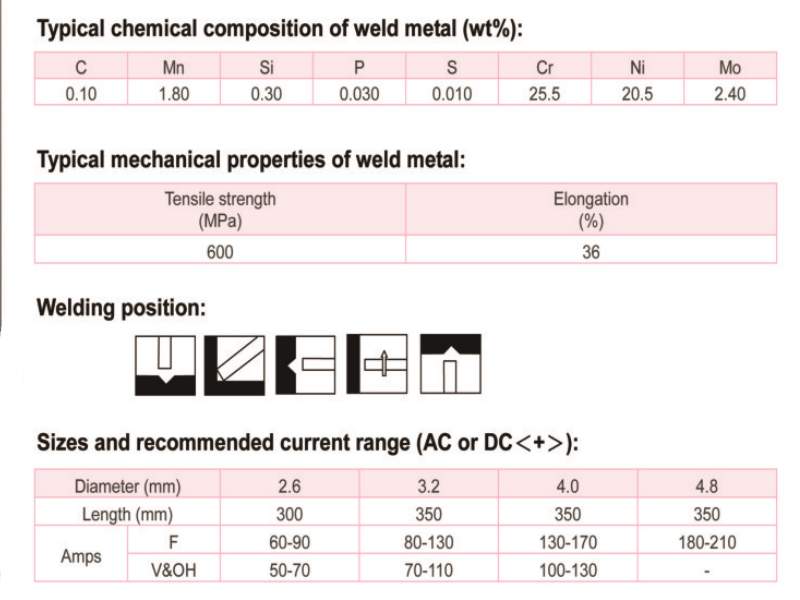

Heat resistance corrosion and toughness of E 310Mo are good.The weld metal is a full austenitestructure containing 25%Cr-20%Ni. lt is not necessary to pre-heat and post-weld heat treatment. lt is suitablefor the dissimilar metals welding, low-temperature service stainless steel,AISI 310S steel, mild steel, and Cr-Mo steel.

Email: max.wang@jthweld.com

E310Mo-16

AWS A5.4 E310Mo-16

Characteristics and Applications:

Heat resistance corrosion and toughness of E 310Mo are good.The weld metal is a full austenitestructure containing 25%Cr-20%Ni. lt is not necessary to pre-heat and post-weld heat treatment. lt is suitablefor the dissimilar metals welding, low-temperature service stainless steel,AISI 310S steel, mild steel, and Cr-Mo steel.

Notes on usage:

1.Be sure to clean up the contaminations on the base metal, groove and pass to pass with stainless steelbrush.

2.Maintaining short arc length as possible is highly recommended.While welding with weave method, movingrange should be controlled within 2.5 times of the wire's dia.

3.Dry the electrodes at 250~300℃ for 60 minutes before use. Take out a batch of half day consumption andkeep in the environment at 100~150℃ during welding process.

4.Due to the austenitic matrix containing intensive Cr, Ni, use lower current and maintain temperature under150℃ to prevent from cracker caused by high temperature.

Have Any Question?

Please Leave your message you want to know! We will respond to your inquiry within 24 hours!